Food Safety- From Farm to Fork

This week's safety bulletin discusses the importance of food safety and dives into how to best practice this. Read the full safety bulletin here and subscribe to receive future safety bulletins straight to your mailbox.

More than 16% of the U.S. population gets sick each year from foodborne pathogens. Put another way, that's 48 million people, or 1 in every six, that get sick from something that may be preventable. Of that percentage, 128,000 are hospitalized, and 3,000 die each year. According to 2023 data from the Centers for Disease Control and Prevention, this percentage has grown 2% from years prior.

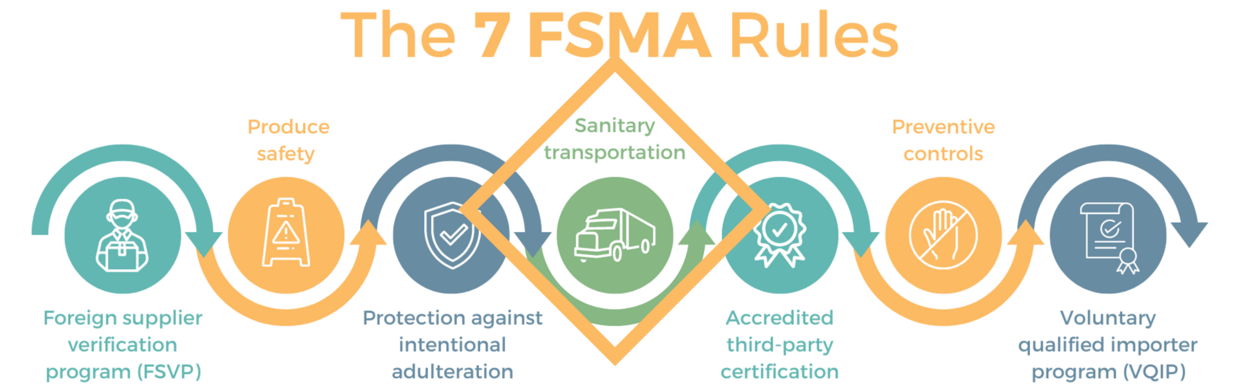

The Food Safety Modernization Act (FSMA), passed in 2011, includes a traceability compliance rule that will go into effect on January 20, 2026. At that time, each link on the "Cold Chain" of safe food transportation must track certain high-risk food ingredients such as fresh fruits and vegetables, eggs, nut butter, cheeses, and seafood products.

Specifically, the FSMA compliance rules apply to foods regulated by the FDA. Granted, this is a significant amount of the U.S. food supply, about 75%. Other agencies regulate the remaining 25%, such as the United States Department of Agriculture (USDA), which oversees meat, poultry, and dairy products.

If you're wondering if this applies to you, if you have to register with the FDA as a food manufacturing facility, the odds are incredibly high that you must comply with FSMA and any new compliance rules. There are exemptions to FSMA, so check the FSMA if you need to check whether or not you qualify.

How does this happen?

In a scenario where multiple people are infected by food consumed from numerous restaurants or grocery stores, investigators will look for a point of convergence within the supply chain. They will trace it back and identify that ingredient. With restaurant dishes, they may look at multiple components, like lettuce, tomatoes, cilantro, white and green onions. Any one of those could be associated with illness.

What are the practices recommended by the FDA to protect the food supply?

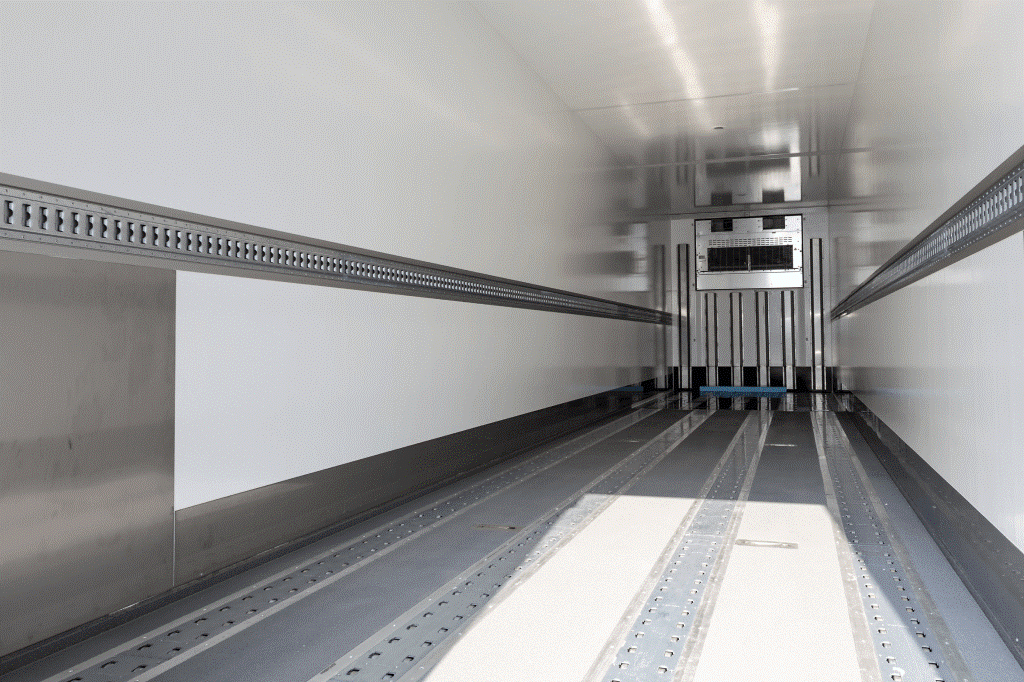

In addition to having a clean pre-cooled compartment that is adequately loaded to ensure optimum airflow around the product, the FSMA has also established procedures for the exchange of information about prior cargos, cleaning of transportation equipment, and temperature control between the shipper, carrier, and receiver. Shippers will need this information to ensure adequate sanitation practices are used, which would help prevent adulteration of transported products. For example, a carrier transporting nut-free foods would want to ensure that vehicles that have previously transported peanuts or tree nuts will not introduce allergens into nut-free foods through cross-contamination.

How to Ensure a Clean Temperature-controlled Compartment

At the end of each day, select an area free of environmental concerns for cleaning the inside of the trailer/truck body. Start by opening the doors of the refrigerated compartment and remove any items that should not get wet. Sweep debris or blow out the case with an air hose after carefully clearing any debris (paper, plastic wrap) from the compartment and inspecting the evaporator housing to remove any residue.

- Prepare a bucket of food-grade detergent and water.

- Scrub all interior surfaces with a clean cloth and detergent/water mix.

- Use a water hose to spray the inside compartment. Make sure to spray the ceiling and walls as well as the floor. Give special attention to cracks, crevices, and areas near door openings and pockets. All cleaning should follow a "top first, bottom last" approach.

- Allow the inside compartment to air dry.

- Shut doors and take other steps, as necessary, to keep your vehicle clean. Always ensure no debris is left in the compartment at the end of your day.

- When dirty, wash the outside of the trailer/truck.

How to Mitigate Risk When Transporting Temperature-controlled Product

- Proper packaging is essential. Packaging should be crush-proof and have solid sides for frozen products and vented sides for fresh products.

- Pre-cool and store cargo at the desired temperature to remove heat. Confirm that the product is at the desired temperature before loading. Refrigeration units maintain temperature, not change it.

- Run the reefer unit for 20 minutes in "high-speed cool." To remove residual trailer/body heat, perform an automatic "pre-trip" test to confirm proper unit operation. Unit MUST pass the test. If the auto pre-trip fails, follow your company's prescribed procedures or contact your maintenance provider for repair.

- Set the unit controller to the desired temperature. Verify the setting after changing it to confirm that it is correct.

- Verify the correct mode of operation. Frozen products are typically transported in auto-stop-start (Cycle-Sentry) to conserve fuel. But this setting can reduce the shelf life or ruin an entire load of produce like fresh fruits and vegetables. Operate the unit on the "continuous run" setting.

- Pre-cool trailer/truck body. Operate the unit to the desired temperature to remove residual heat.

- Turn the unit "OFF" while loading. To minimize heat & humidity entering the trailer/truck body and verify the product is at the proper temperature.

- Load product quickly and efficiently. Provide adequate air circulation around and through the entire load.

- Close the doors and start the unit. Re-confirm Continuous Run or Auto-start-stop operating modes and temperature setpoint are correct. When the compartment temperature is below 40°F, initiate a defrost cycle. Doing this will help clear the evaporator coil and ensure maximum cooling performance.

- Strip curtains are always recommended in the distribution of temperature-controlled products. These curtains keep conditioned air in and outside air out.

- Door openings. Minimize the number of door openings and their duration. Ambient air migrates in, and trailer/body air migrates out.

- Proper airflow is CRITICAL. Poor air distribution causes product deterioration, even with adequate unit capacity. Obstructions cause poor air flow and produce hot spots. Good air circulation allows unobstructed paths on all six sides of a load.

Atlanta Idealease to Hold an Open House and Debut the New Navistar eMV Battery Electric Medium Duty Truck!

If you are interested in attending and participating in the ride and drive in Atlanta, register now using this link: AtlantaOpenHouse_eMV

Time to Fall Back…..Daylight Savings Time Changes on Sunday November 5th!

Daylight savings time will "fall back" at 2:00 a.m. on Sunday, November 5th. Make sure that all your drivers are aware that the change to daylight savings will occur. Caution route drivers especially that the amount of daylight will change according to their stops with the change. An intersection or street can present different challenges to drivers with one hour change in the position of the sun. One hour of time difference can present unique changes to a driver who is on a route.

*The Idealease Safety Bulletin is provided for Idealease locations and their customers and is not to be construed as a complete or exhaustive source of compliance or safety information. The Idealease Safety Bulletin is advisory in nature and does not warrant, guarantee, or otherwise certify compliance with laws, regulations, requirements, or guidelines of any local, state, or Federal agency and/or governing body, or industry standard.